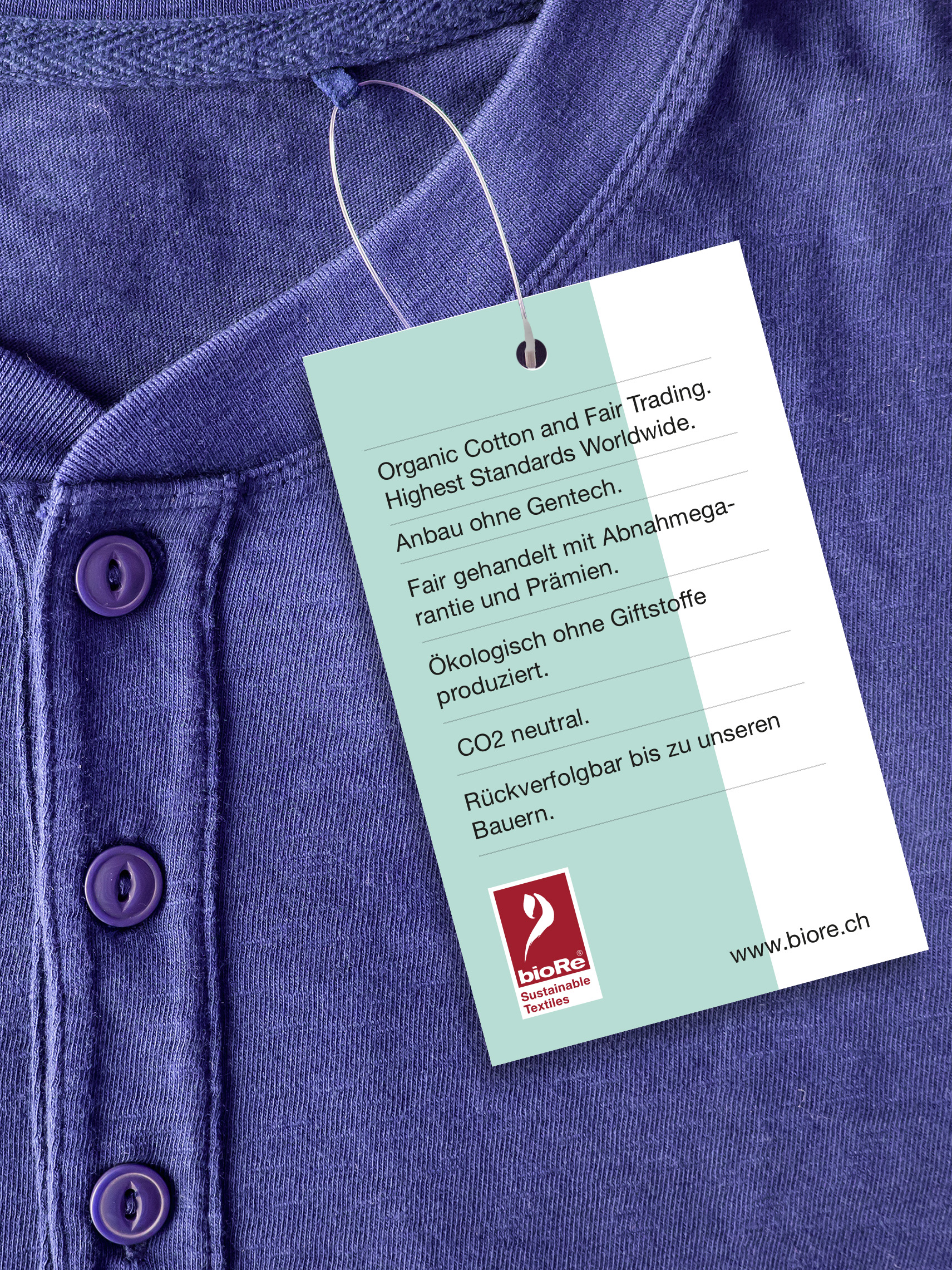

Remei is one of the first textile manufacturers to produce 100% CO2-neutral since 2013.

Together with its partners, the company strives to use resources sparingly and is always looking for the best possible solutions. By financing biogas plants and efficient stoves for farmers in the organic cotton growing areas in India and Tanzania, the textile manufacturer offsets its CO2 consumption at the beginning of its own supply chain. In this way, the consumption of firewood can be reduced and a circle is closed. The bioRe® Sustainable Textiles label guarantees the climate-neutral production of an organic cotton textile and offers consumers guidance when shopping.

The implementation of the CO2 projects is conducted by the bioRe® Foundation in cooperation with the bioRe® Foundation Tanzania. In 2019 alone, it was able to build 1,000 new efficient stoves for bioRe® farming families. For orientation:

300 efficient, smokeless stoves save about as much CO2 as the production of about 100,000 T-shirts.

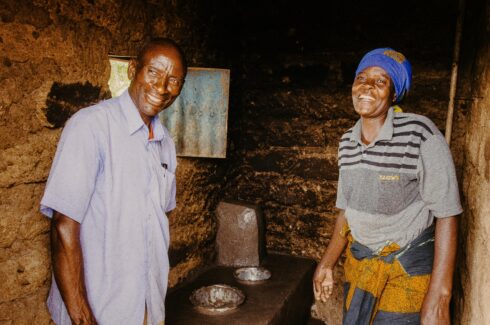

Amina Hussein from Mwambegwa village has had a smoke-free stove since 2009 and is still enthusiastic: “The stove allows almost smoke-free operation – only a little smoke is produced when it is lit. It cooks quickly, and when it gets hot, it loses heat very slowly. The embers last until the next day.”

The funds from the compensation also flow into training for the construction and maintenance of the stoves. Recently, 2 female stove builders were employed for the first time; until now, stove building was a purely male domain.

Holo Norbert, who became one of the first stove builders commissioned by the bioRe® Foundation at the age of 22, says of her professional motivation:

“I want to become an expert stove builder and educate our community about the benefits of this stove model.”

Monica Paul, who also learned stove construction at bioRe, adds:

“It is important to build such cookers because it reduces firewood consumption by almost half compared to the local cooker (three-stone cooker). Consequently, fewer trees are cut down.”

Markus Kunz, Supply Chain Manager at Remei AG sees the potential for further expansion of the CO2 compensation project:

“The stove is perfectly designed for the local environment and is accordingly well received by the farming families. As a result, we can build more stoves.”